Have you ever wanted a workshop with the tools to build or make anything? What if this workshop also had a community of friends, each with different skills and experiences in technology, who loved to share their knowledge with others because they have a passion for it, love it, and live it? HackPittsburgh is that workshop of your dreams! HackPittsburgh offers amazing tools, and amazing people, and we have been doing this since 2009! We are proud to be Pittsburgh’s first Makerspace!

We have many events which are open to the public and usually free, where people can come in for interesting talks or presentations and see the shop and what we have to offer. See the calendar.

We have two days a week Monday and Saturday nights at 7:30pm when the shop is open to the public and someone is guaranteed to be there. This is the best time to come and get a tour of HackPittsburgh.

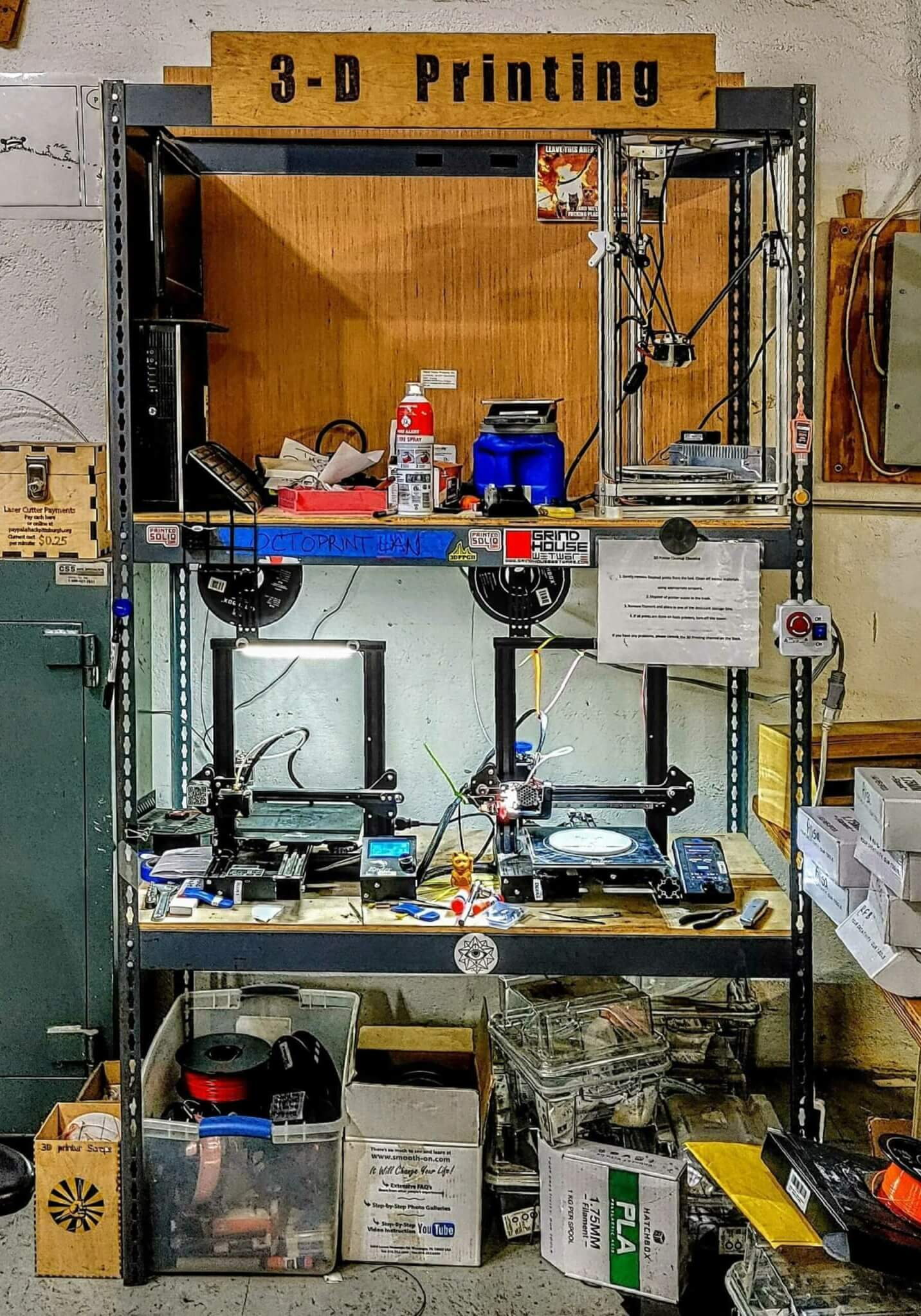

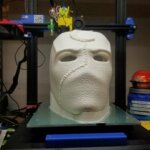

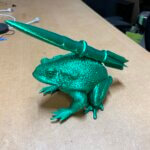

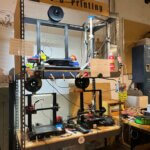

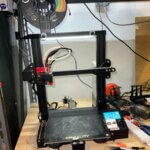

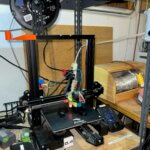

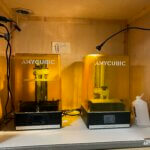

3D Printing

HackPittsburgh is home to multiple kinds of 3D printers. Whether you're printing ABS, PLA or resin, you'll find what you need here.

Currently, we have two FDM printers, both of which are Ender 3s with heated beds.

We also have two SLA printers.

We are constantly working to get more 3D printers, and constantly upgrading and improving the printers we have. We have also hosted presentations from leaders in the 3D printing industry, such as 3DPPGH, Ultimaker, MatterHackers, and Make Magazine.

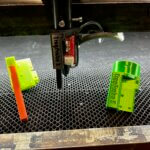

Laser Cutter

We have a powerful and extensively customized 150W laser cutter with a 600 x 900 mm bed. It can cut most wood, acrylic, leather, wool, and certain types of rubber. It can etch wood, acrylic, glass, granite, glazed ceramics, and many other types of materials. Trogdor Mark II boasts a number of recent upgrades made in-house, including but not limited to a 3D printed autofocus probe, a highly efficient custom-fit exhaust fan, and simple but effective interior lighting.

Woodshop

The HackPGH woodshop is a spacious area equipped with a large 10 inch blade table saw with an extended fence for cutting large sheets. Other tools include a miter saw, drill press, grinder, 10 inch thickness planer, 14 inch bandsaw, router table, 4 inch jointer, and free standing belt/disk sander with 5 inch belt and 12 inch disk. We are also equipped with multiple hand tools including orbital sanders, belt sanders, circular saws, jig saws, etc.

Metalworking

HackPGH’s Metal Fabrication Area is well equipped for most prototyping and hobby level needs. The metal shop consists of both welding/fabrication and machining equipment.

The welding area is a 120 sq ft space surrounded with welding curtains and at the center lies a 5ft by 5ft steel welding table that can be used for all of your fabrication needs. The workhorse of our welding setup is our 130 amp Lincoln MIG welder. Other equipment includes a plasma cutter, a small stick welder as well as a small TIG machine with limited capabilities. For prep work and other fabrication needs HackPgh provides a 30" shear/brake and slip roll combo, as well as a ¼ hp rotary hacksaw that can be used to cut various metals. Other tools provided include a bench grinder, sawzalls, hand grinders, drill press and various bits and accessories.

HackPgh also has the ability to do lite machining with both our manual drill mill and metal lathe. Our Grizzly drill style mill is DRO readout equipped and also has a rotary indexing table to allow the operator to drill or cut work at exact intervals around a fixed horizontal or vertical axis. HackPgh also has a 12” x 36” Atlas lathe (also DRO Equipped) which includes a 5” Three jaw and an 8” Four jaw chuck. We are also equipped with all necessary tooling and meteorological equipment required for your projects!

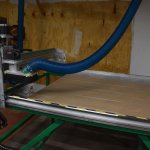

CNC Mill

Electronics

We have everything you need for your electronics project. Lots of components: resistors, capacitors, inductors, transistors, IC chips, and etc. Analog and digital oscilloscopes, multimeters, power supplies, digitally controlled soldering iron, and many variable power soldering irons, we even have a de-solderdering iron. Lots of cutters, wire strippers, solder suckers, breadboards, perfboards, and any other tool you can imagine. We also have the ability to mill our own PCB’s using our CNC machines.

Soft Arts

The Soft Arts area features an embroidery machine,multiple sewing machines, a vinyl cutter, a full size plotter, a large format laminator and its letter-sized cousin, and numerous other tools and materials for all of your foam, fabric, paper, and thread related projects.

We have a number of members who regularly create amazing costumes for various local conventions and other cosplay events. Below are photos of some of the amazing things they have made using the tools in our fabrication area.

Kitchen Area

Makers often spend long hours making awesome stuff at HackPGH and get hungry. We have a complete kitchen area with everything you need to heat up your food, and free coffee and popcorn for members! We also have vending machines where you can buy snacks, drinks, and even electronics such as Arduinos and other microcontrollers. You may also notice our award winning Power Racing Series Electric GoKart Delorean on top of the vending machine.